Define Floor Temperature Polymerization

Is the temperature below which polymerization cannot occur.

Define floor temperature polymerization. Above the ceiling temperture depolymerization an unzipping reaction to reform monomer occurs. For additional support visit our visitor services page. Nbr is used in the automotive and aeronautical industry to make fuel and oil handling hoses seals grommets. Thus the net rate of polymer growth is zero.

8 117d the reported examples include. A related issue is temperature control also called heat management during these reactions which are often highly exothermic. Experimental studies of the spontaneous thermal polymerization of mma at high temperatures 100 130 c showed the production of high average molecular weight polymers low conversion of monomer to polymer and the formation of a significant amount of oligomers such as dimers and trimers after 75 hours of batch operation 10 14 23. In floor radiant design guide.

Ceiling temperature is a measure of the tendency of a polymer to revert to its constituent monomers when a polymer is at its ceiling temperature the rate of polymerization and depolymerization of the polymer are equal. Above the ceiling temperature depolymerization will occur and the polymer will revert to its monomer. Is the temperature at which propagation and depropagation are equal. Heat loss to head loss validating radiant cooling and heating designs new software solutions how to use the ashrae radiant design graph for sensible heating and cooling.

Polymerization definition is a chemical reaction in which two or more molecules combine to form larger molecules that contain repeating structural units. Alkyl vinyl ether. Living polymerization is most frequently employed for the synthesis of block copolymers where two or more monomers are polymerized sequentially and this is not exceptional for the hi i 2 initiated living polymerization of vinyl ethers. People who visited this page also visited.

Methyl vinyl ether hexadecyl vinyl ether. For example for the polymerization of ethylene 93 6 kj of energy are released per mole of monomer. The manner in which polymerization is conducted is a highly evolved technology. For addition chain polymerization the temperature at which the propagation and depropagation rates are equal that is the net rate of polymer formation is zero.

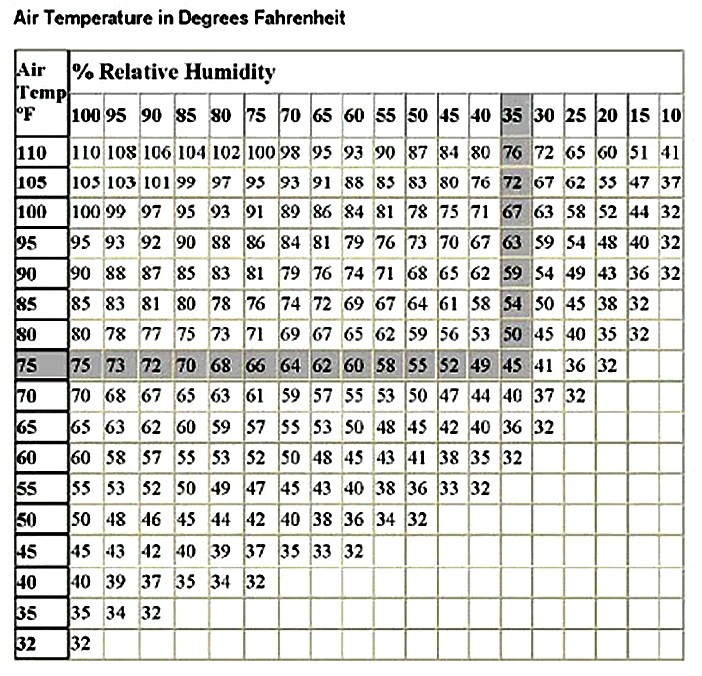

Generally the ceiling temperature of a given polymer is correlated to the steric hindrance of the polymer s monomers. Recommended floor temperatures for bare feet and for those wearing shoes. Trade names include perbunan nipol krynac and europrene this rubber is unusual in being resistant to oil fuel and other chemicals.